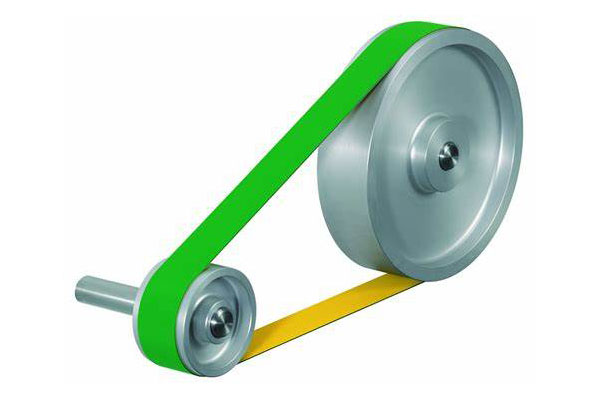

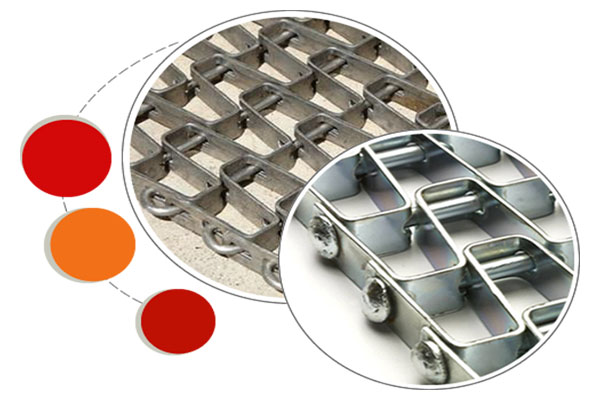

Toothed belts are one of the most common belts we deal with. A toothed belt, also called a synchronous belt, is an extremely popular form of power transmission. As you can imagine, they have no slippage when properly applied.

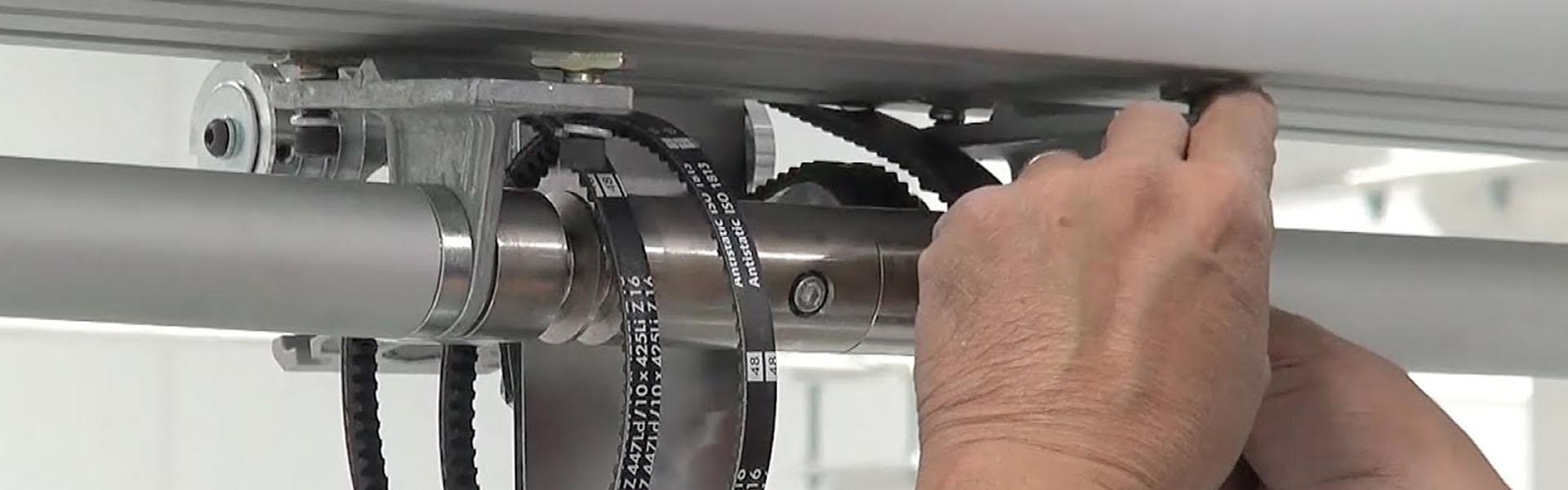

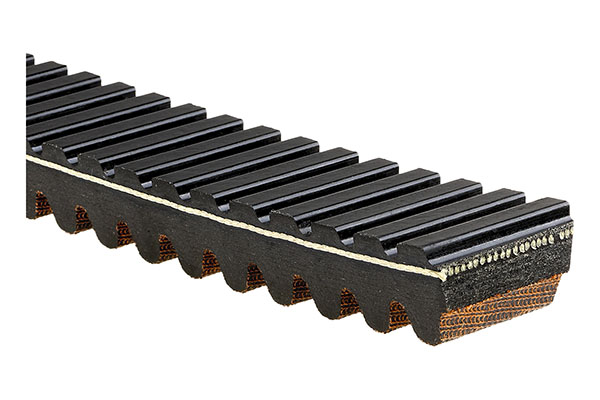

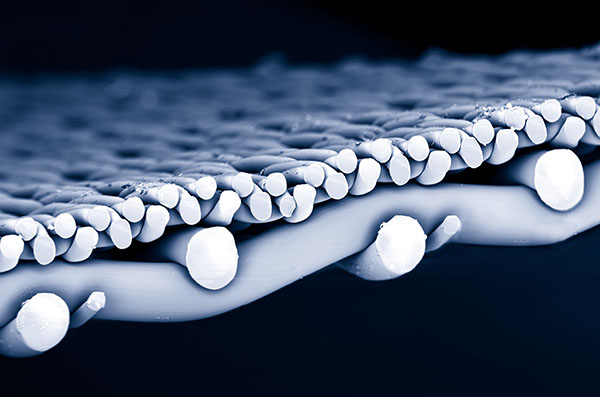

Toothed belts are one of the most common belts we deal with. A toothed belt, also called a synchronous belt, is an extremely popular form of power transmission. As you can imagine, they have no slippage when properly applied.They are recognizable by their distinctive "teeth" that prevent slipping, although if they are not properly tightened things can go really wrong.

The design of the toothed belt is such that it can deliver much more power than a standard friction drive belt cannot, and it is extremely rare for a toothed belt to break unless stone or other material gets into it.