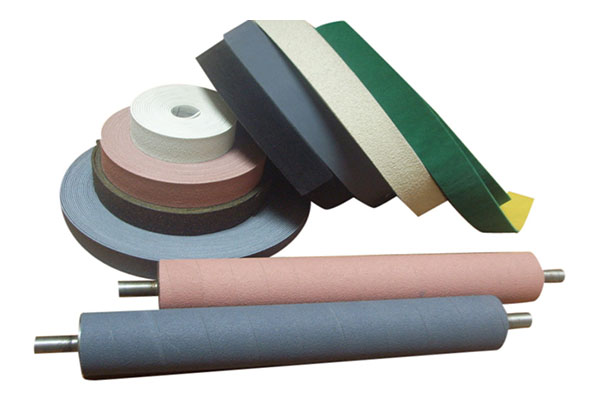

Drum covers - thanks to the use of a properly selected veneer, we increase the friction coefficient between the belt and the drum. This is the easiest and fastest way to reduce slippage and increase circumferential force when the belt is too weak for the increased load, and the tensioning range is practically over, and also when we cannot tighten the belt too much, because it will lead to too large deflections fragile drive drums and belt guiding problems.

Drum covers - thanks to the use of a properly selected veneer, we increase the friction coefficient between the belt and the drum. This is the easiest and fastest way to reduce slippage and increase circumferential force when the belt is too weak for the increased load, and the tensioning range is practically over, and also when we cannot tighten the belt too much, because it will lead to too large deflections fragile drive drums and belt guiding problems.The veneer for drive drums is usually self-adhesive veneer. These are thin strips with a textile base coated with glue on the underside and covered with various materials and rubbers with different structures.